Projects

Vision application

We use cameras without internal logic in our applications because we handle the logic on a PC, which provides access to greater computational power and processing capabilities. All “GigE Vision” cameras are compatible with our systems. However, we do consider cameras with internal logic for specific applications.

We have experience with linescan cameras, 3D cameras, and cameras with area sensors (standard). The choice of camera will depend on your application.

-

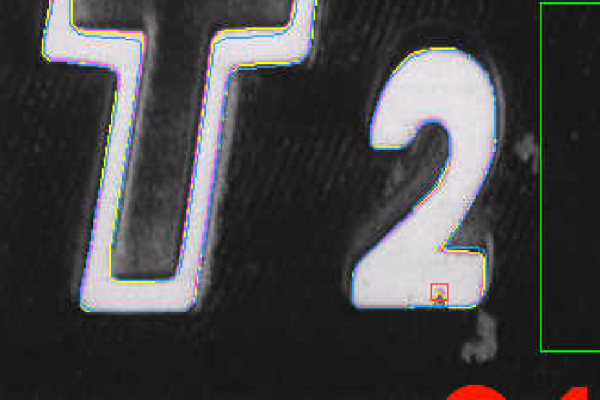

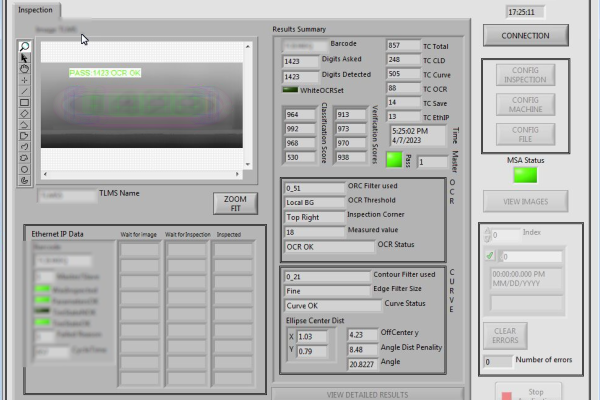

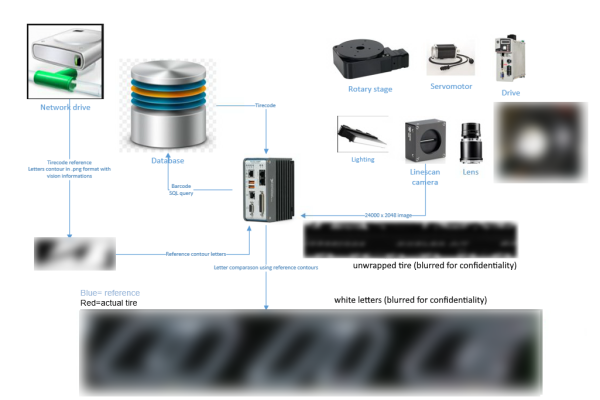

Inspection of tire lettering quality with over 100 types and 50+ patterns per type, barcode association, and SQL integration.

-

Inspection of position and authentication of numbers during tire engraving.

-

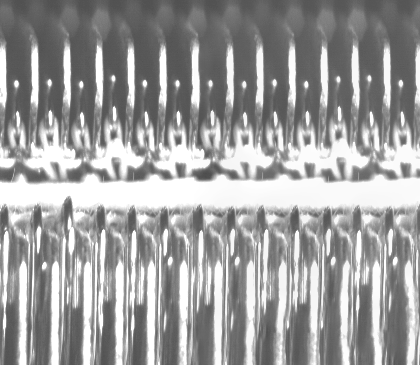

Inspection of needles at 800 images per second.

Inspection of web handling equipment — Vision and robotics

We have acquired specialized knowledge in inspecting and controlling web equipment by leveraging our expertise with linescan cameras, servomotors and real-time system programming. This particular application demands meticulous coordination and seamless interaction among different electrical and mechanical elements.

Please consider us if you have rotating parts that require inspection or if you have processes involving web handling, such as printing, textiles, paper, rubber, etc.

-

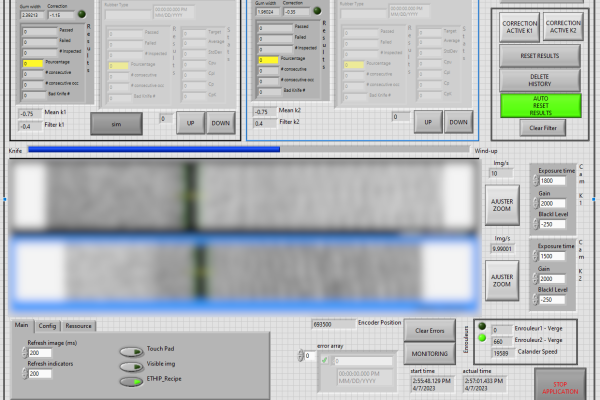

Control and inspection of rubber cutting at speeds exceeding 800mm/sec and 250 images/sec, with a cutting accuracy of +/- 0.3mm.

-

Inspection of web edges.

Axis control — Robotics

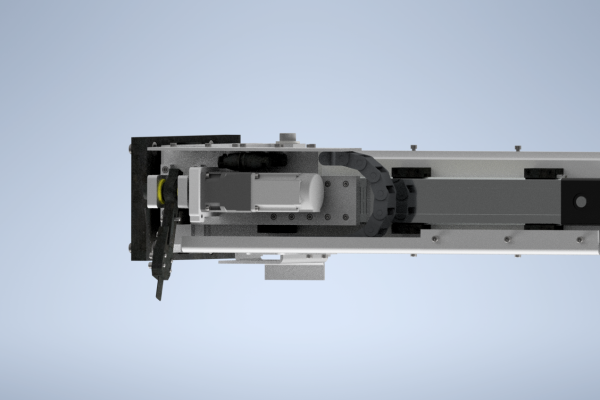

We have a strong experience with servo motors, and our first project (prototype) dating back to 2009 was a significant challenge. We designed a three-axis motion assembly for deburring metal tubes of various sizes. The motion control was custom-programmed on an FPGA, allowing the synchronization of the three axes to create custom-shaped deburring based on the tube type, in conjunction with a fourth axis.

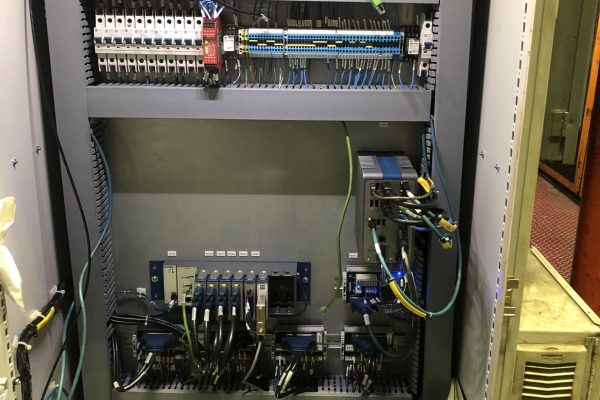

Currently, we work with EtherCAT drives, but certain technological complexities may still require FPGA-level motion programming if necessary.

- 3-axis servo control deburring machine (metal industry).

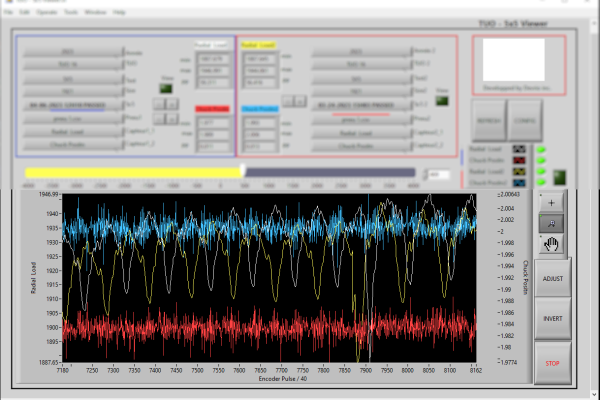

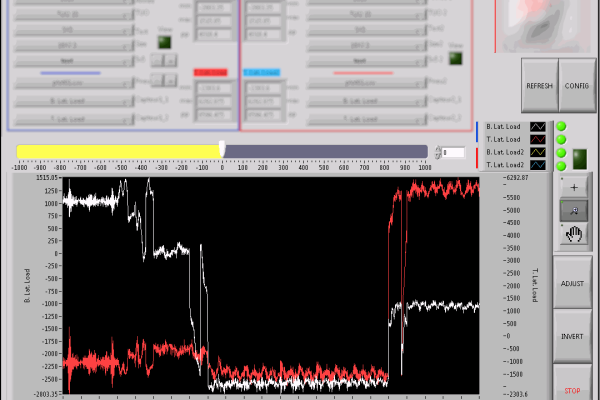

Data acquisition and signal analysis tools are essential for the success of automation projects. They allow us to verify the robustness of our solutions, and using real and offline available data enables us to simulate machine behaviors. This phase of the project prepares and reduces the probability of problematic commissioning.

From a quality standpoint, data also allows us to verify the statistics of an inspection process and helps pinpoint problematic machines.

From a maintenance perspective, diagnosing complex machines can be challenging. Designing visualization tools enables simultaneous monitoring of multiple sensors based on a specific variable. Analyzing these signals helps detect anomalies, whether through human analysis or AI techniques.

Even if these data may seem abstract and unnecessary at the moment, it is recommended to retain them and seek the assistance of an expert to store them intelligently.

- Acquisition software for diagnosing complex machines in a tire factory.

- Control and inspection project for rubber on web handling equipment, including calculations.