Installation of cameras or sensors on your process for data acquisition.

AI

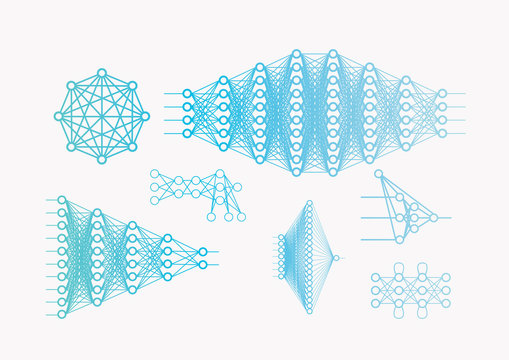

AI (Artificial Intelligence) has exploded in recent years, with significant progress in research, innovation, and its practical applications. The increase in computing power, data storage, and open-source libraries like Tensorflow and PyTorch are the main drivers behind this explosion. This advancement has made AI accessible to everyone.

A simple and concrete example of an imaging problem that was previously impossible to program with traditional algorithms is distinguishing between an image of a dog and a cat. With AI, a model with a few layers and just a few lines of code can be trained to achieve this differentiation with excellent results.

AI can therefore solve inspection or process control problems that were previously considered impossible. Think about the shapes, textures, and subtle defects in your processes. It is now possible to automate these inspections!

The typical phases of an AI project are as follows:

Data preparation

Selection of regions of interest in an image or signals, data manipulation, data classification.

Training

Development of a model/network architecture, training.

Model validation

Analysis of model metrics, adding/removing layers as needed.

Model deployment

Deployment of inference/reasoning on your process, testing in production!

Model maintenance

Updating the model based on new types of data or defects.